Article Preview

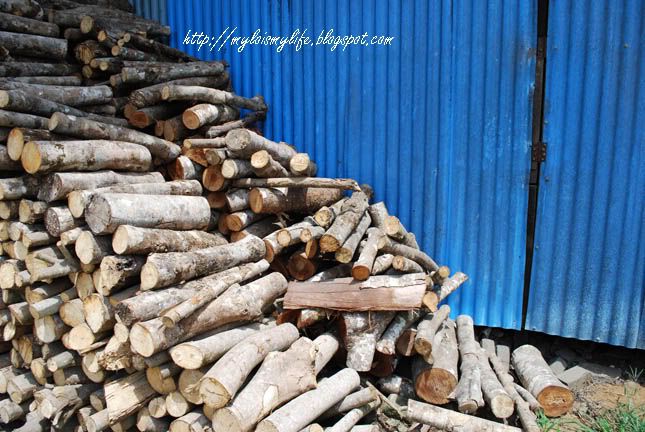

Title: Stack it UP

Location: Charchoal Factory, Taiping, Perak, Malaysia

Date: 4 June 2009, 12:20pm

Camera: Nikon D60 with Aperture: f/5.6, ISO Equiv.: 100

A huge pile of harvested mangrove trees. Workers will select and organize the logs according to the stem diameter.

Title: Chopped

Location: Charchoal Factory, Taiping, Perak, Malaysia

Date: 4 June 2009, 12:20pm

Camera: Nikon D60 with Aperture: f/6.3, ISO Equiv.: 100

The mangrove trees were cut into smaller parts. The bark will be removed before the trees are cook in the igloo shaped kiln.

Title: Assorted Mangrove Logs

Location: Charchoal Factory, Taiping, Perak, Malaysia

Date: 4 June 2009, 12:31pm

Camera: Nikon D60 with Aperture: f/3.5, ISO Equiv.: 250

Usually, only mangrove trees aged 30 and above are harvested. But, these skinny logs seems to be lesser than three decades.

Title: CHOPPED & STRIPPED

Location: Charchoal Factory, Taiping, Perak, Malaysia

Date: 4 June 2009, 1:45pm

Camera: Nikon D60 with Aperture: f/6.3, ISO Equiv.: 100

After the mangrove trees or bakau minyak are harvested from the 40,466ha forest reserve, they are cut into roughly 1.6 metre logs and the bark is stripped.

Title: NAKED

Location: Charchoal Factory, Taiping, Perak, Malaysia

Date: 4 June 2009, 1:44pm

Camera: Nikon D60 with Aperture: f/7.1, ISO Equiv.: 100

The mangrove bark were removed to reduce excess moisture.

Title: Getting Ready

Location: Charchoal Factory, Taiping, Perak, Malaysia

Date: 4 June 2009, 12:27pm

Camera: Nikon D60 with Aperture: f/3.5, ISO Equiv.: 360

These mangrove logs will be placed in a kiln (usually shaped like an igloo). Here, the logs are smoked to remove the water from them. To create the smoke, other mangrove wood is burnt, such as non-Rhizophora species like Bruguiera, Xylocarpus and also the unwanted prop roots from Rhizophora apiculata.

Title: Keep it BURNING!

Location: Charchoal Factory, Taiping, Perak, Malaysia

Date: 4 June 2009, 12:36pm

Camera: Nikon D60 with Aperture: f/3.5, ISO Equiv.: 1600

This fire heats up the kiln and water will start to vaporize from the logs. The inner temperature is 220°C. The hole is still half open and the fire is burning. The first stage of this process takes around 8 to 10 days.

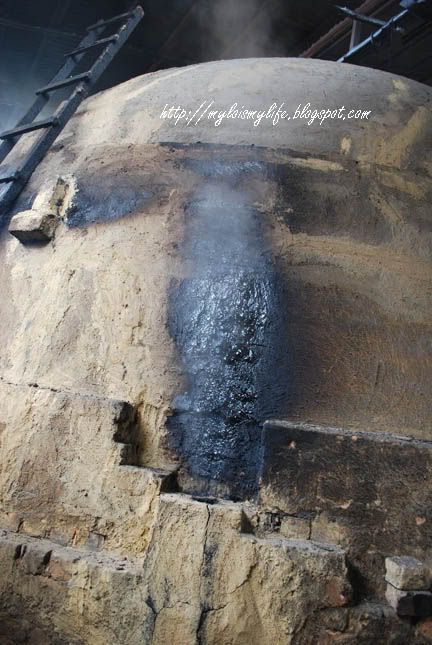

Title: A Sealed Kiln

Location: Charchoal Factory, Taiping, Perak, Malaysia

Date: 4 June 2009, 12:33pm

Camera: Nikon D60 with Aperture: f/3.5, ISO Equiv.: 1600

After 10 days, the kiln is completely sealed and the baking process continues on a temperature of around 83°C. This takes another 12 to 14 days. Then the cooling process starts, this takes another 8 days before the hole in the kiln is opened.

Title: It's really HOT!

Location: Charchoal Factory, Taiping, Perak, Malaysia

Date: 4 June 2009, 12:30pm

Camera: Nikon D60 with Aperture: f/3.5, ISO Equiv.: 1400

I was touching the sealed part of the kiln. As hot as a boiling kettle!

Title: The Charcoal Kiln

Location: Charchoal Factory, Taiping, Perak, Malaysia

Date: 4 June 2009, 12:58pm

Camera: Nikon D60 with Aperture: f/3.5, ISO Equiv.: 360

An experienced worker can tell the condition of the log by feeling the vaporized water/smoke that comes out of the holes of the kiln.

Title: Secret Recipe

Location: Charchoal Factory, Taiping, Perak, Malaysia

Date: 4 June 2009, 1:04pm

Camera: Nikon D60 with Aperture: f/3.5, ISO Equiv.: 720

Two main ingredients to make the charcoal kiln.

Title: GIMME CLEAN AIR

Location: Charchoal Factory, Taiping, Perak, Malaysia

Date: 4 June 2009, 12:45pm

Camera: Nikon D60 with Aperture: f/5.3, ISO Equiv.: 1600

A malfunction fan.

Title: The Packaging Section

Location: Charchoal Factory, Taiping, Perak, Malaysia

Date: 4 June 2009, 1:50pm

Camera: Nikon D60 with Aperture: f/3.8, ISO Equiv.: 200

The charcoal factory was hot, humid and stuffy. Thick black charcoal dust were flying all over the place.

Title: Packaging Charcoal

Location: Charchoal Factory, Taiping, Perak, Malaysia

Date: 4 June 2009, 1:51pm

Camera: Nikon D60 with Aperture: f/5.3, ISO Equiv.: 280

An old lady sorting out charcoals to be wrapped with paper bags. This section is separated from the charcoal kilns. So, the air is a bit cleaner.

Title: All Bundled Up and Ready to Go

Location: Charchoal Factory, Taiping, Perak, Malaysia

Date: 4 June 2009, 12:38pm

Camera: Nikon D60 with Aperture: f/3.5, ISO Equiv.: 1600

Thirty-six bundles of charcoal to be exported to Korea and Japan as BBQ charcoals.

Title: BEHOLD A Charcoal

Location: Charchoal Factory, Kuala Sepetang, Perak, Malaysia

Date: 4 June 2009, 12:40pm

Camera: Nikon D60 with Aperture: f/5.6, ISO Equiv.: 1250

Mangrove charcoal is considered superior for cooking to regular coal because it burns longer and produces less smoke. Locally, it is used to cook favourites such as satay and seafood. The retail price of charcoal has gone up from 50 sen a kilogramme to RM1.60

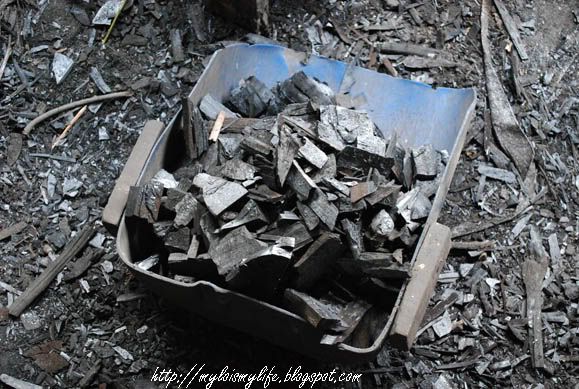

Title: Nothing Left to Waste

Location: Charchoal Factory, Taiping, Perak, Malaysia

Date: 4 June 2009, 12:38pm

Camera: Nikon D60 with Aperture: f/5.3, ISO Equiv.: 1600

Smaller pieces o f charcoal are normally sold at a cheaper price.

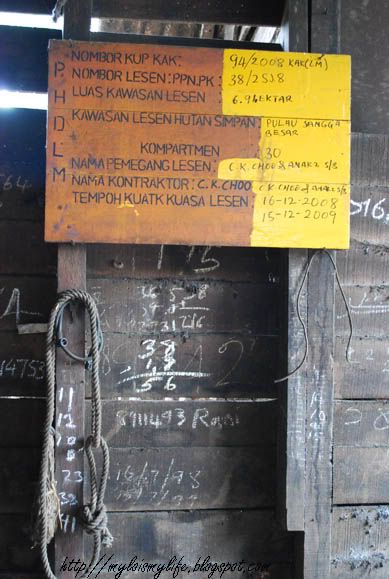

Title: Liscene to CHOP & BURN

Location: Charchoal Factory, Taiping, Perak, Malaysia

Date: 4 June 2009, 12:54pm

Camera: Nikon D60 with Aperture: f/4.8, ISO Equiv.: 1400

All charcoal factories need to display this board. It has information about total area that can be log, validity of the license and place to log.

After exiting the mangrove forest, I asked around for the direction to Taiping’s famous charcoal factories. The charcoal factories are located across the street from the mangrove forest. There is no signage. I was walking into the factories when some school teens yelled at me “WEI!!!” “OOI!”. I WAS LIKE “HUH?” Do I know them? They told me a forest ranger like to speak to me. So, I met up with this guy and noticed he was the same person I met earlier in the ranger's office. He was conducting a study tour for the high school teens. He told me to seek permission from the factories owners before taking any photos. I thanked him for his advice.

I was walking along the stony lane when I bumped into two Chinese guys. It was strange. Nobody was talking. So, I broke the silence by asking them if I can survey the charcoal factories and take some personal photos. One of them answered “Yes, you can. But, only in my factory not others. You have to obtain permission from them”. This fella owns three dapur arang (Translation “Charcoal Kiln”). The area has more than 90 kiln to cook raw mangrove trees into pure black charcoal.

The Chinese guys informed me some bosses do not like photographer lingering in their factories and they prefer a low profile. These charcoal kilns belong to either Chinese or Malay bosses. After the brief chat, I walked into his factory. The inner factory was extremely stuffy with black charcoal dust flying everywhere! I was sweating and barely breathing. But, the place is BEAUTIFUL! WHY? Because, I’m so fascinated with the processing of mangrove trees into charcoal. I can see workers transporting freshly chopped mangrove trees into the factory, slicing them into manageable sizes, skinning the trees, burning it into perfected charcoals and packing them for export to Japan and Korea as BBQ coals.

Later, I moved to another factory belong a Malay boss. The big boss is not around that afternoon. So, I just walked in and bumped into a 40++ year old worker. I chatted with him for almost an hour long. It was supposed to be a brief introduction on my side. I guess I was too engrossed with the charcoal business. I asked lots of questions. Through the conversation, I understand he has been working in the factory since he was a 15 year old teen – over 25 years of working experience but still earning a mere RM500 per month!

I also learnt from him every boss has exclusive rights to cut down sizable number of mangrove trees depending on the number of kilns. Each charcoal kiln can last for 10 to 15 years. Poorly constructed kilns will collapse in less than 5 years. The cost for building one kiln is around RM15 000. But, each kiln is able to generate a minimum income of RM3, 000 per month. So, I guess the Chinese boss who owns three kiln is earning around RM9 000 per month.

It was great talking to him. Snapping pictures in the factory is nearly impossible. It was hot, humid, stuffy and dark. Nonetheless, I still snapped lots of pictures. Most of the workers here do not want to be photograph.

Overall, I truly enjoyed my personal tour to the charcoal factories. A visit to Taiping will not be complete without a visit to the charcoal factories. It was a wonderful experience witnessing the making of charcoal and meeting the people behind the scenes. Later, I took my lunch at Mee Udang Mak Jah stall as recommended by fellow blogger xplorer. This post is already too long.

Mangrove Charcoal Factories - Getting There:

From the motorway, choose Changat Jering junction and follow the direction to Taiping. At the crossroads where you choose right to Taiping, you have to follow the direction to Kuala Sepetang, which is 11 km away. Just before arriving in Kuala Sepetang you will find the Mangrove forest sanctuary. Opposite the forest is the charcoal factories.

More info?

Read these articles before you travel:

Matang Mangrove Forest Reserve & Mangrove-Charcoal Factories – Maps & Manuals:

Click here to view all places of interests in Taiping:

YouTube Video - Matang Mangrove Forest & Charcoal Factory:

Growing near a charcoal factory, I used to buried sweet potato or crabs under the burning logs to cook. It was the best grilled potato and crabs in the world.

Aw

Can you please tell me the address of person who runs this charcoal factory ,I am interested to learn how to make charcoal .